In recent years, noncontact crewless operations have become prominent in the field of environmental disinfection. Robots that automatically disinfect the air and surfaces of hospital environments can help reduce the human resources spent on environmental cleaning and disinfection and minimize the risk of occupational exposure for staff. These robots also facilitate informatized management of environmental disinfection, reduce costs, and increase the efficiency of disinfection efforts.

2667-1026/© 2021 Chinese Medical Association. Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/)

International socioeconomic development and medical reforms have permitted the medical industry to move toward true "intelligence". The incorporation of greater artificial intelligence (AI), 5G technologies, Internet of Things, robotics manufacturing, cyber-physical systems, and other high-tech new technologies enriches the medical profession [1].

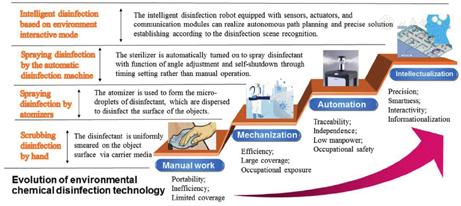

The prevention and control of hospital-acquired infections is the cornerstone of medical safety and a core task in improving medical service quality. The integration of engineering technology and hospital infection management has resulted in breakthroughs in infection control technology. Medical institutions worldwide are optimizing hospital intelligence and collecting and organizing information from various perspectives, building innovative models of hospital development. These models help achieve cost reductions associated with hospital infection prevention and control. Institutions are applying advanced biomedical engineering technology to allow patients to interact with medical staff, medical institutions, and medical equipment and achieve greater informatization and intelligentization. Historically, disinfection practices have become less manual, more mechanized and automated, and finally intellectualized (Figure 1). For hospital infection control, each step of development relies on innovation in engineering technology. During major infectious disease outbreaks, the integration of technological engineering and hospital infection management has played a central role.

The outbreak of the coronavirus disease 2019 (COVID-19) in December 2019 became a significant public health emergency characterized by rapid and widespread infection. The pandemic posed the greatest difficulty in prevention and control since its outbreak [2,3]. At the time of this publication, the COVID-19 pandemic is ongoing worldwide; effective prevention and control remain significant challenges for the international community. As the understanding of COVID-19 continues to grow, the Diagnosis and Treatment Protocol for Novel Coronavirus Pneumonia (Trial Version Eight) added a statement on the transmission route of COVID-19: "Contact with virus-contaminated objects can also cause infection." This addition means that contaminated environments and surfaces are important sources of infection that promote the spread of COVID-19 through physical contact. The role of frontline infectious disease treatment involves a high risk of contamination of environmental surfaces due to high-risk pathogens. Therefore, disinfection of medical institution environments is critical to cut off transmission routes, prevent hospital-acquired infections, and control infectious disease outbreaks [4,5].

Traditional hospital environmental cleaning and disinfection work included manual wiping, chemical spraying, and ultraviolet irradiation; however, it is difficult to guarantee the quality of manual wiping. Aldehyde disinfectants, chlorine-containing disinfectants, peroxyacetic acid, and other disinfectants can cause severe irritation and occupational injury. Ultraviolet lamp disinfection also requires manual operation, and there are limitations associated with the distance of the lamp from surfaces; sterilization is only effective within 1 m, which is too short a distance. Furthermore, ultraviolet light cannot reach shaded areas, leading to inadequate disinfection and numerous dead spots.

Air disinfection in medical institutions requires laminar flow purification systems, ozone disinfectants, and other disinfection equipment; such equipment is expensive and can only be used in fixed locations, introducing installation difficulties. The COVID-19 virus is highly contagious, and patients may move around the hospital (registration, outpatient clinic, observation, examination, and ward) while carrying the virus, creating challenges for traditional disinfection.

On the one hand, it is challenging to achieve quantitative real-time tracking of the disinfection process, including records of task time, place, and actual dosage of disinfectant and the temperature and humidity that impact the disinfection. Without traceable records, there is often insufficient disinfection under ordinary circumstances and excessive disinfection during a pandemic. On the other hand, while killing pathogenic environmental microorganisms in medical institutions, disinfection personnel risk occupational exposure. The pandemic severely taxed medical resources in a short period. In addition to a shortage of personal protective equipment, there were also shortages of environmental cleaning and disinfection professionals. This lack of human and material resources posed substantial challenges to the environmental disinfection work of medical institutions, severely affecting the overall prevention and control of the pandemic.

In recent years, noncontact crewless operations have become prominent in the field of environmental disinfection. The use of agile and intelligent robots to perform environmental disinfection at the source of infection reduces labor costs and (more importantly) efficiently and safely reduces occupational exposure of disinfection personnel.

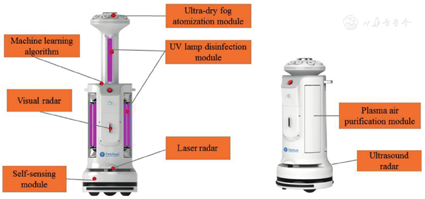

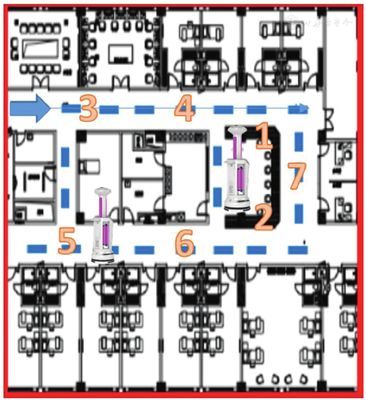

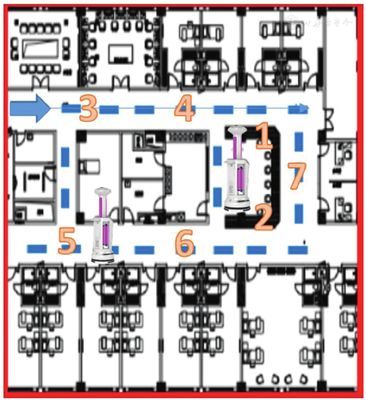

The disinfection robot was developed based on an AI algorithm. The algorithm permits interaction between the disinfection machine and the disinfection site. The AI disinfection robot uses sensors to identify dynamic disinfection scenes (Figure 2). 3D modeling of a high-precision scene is built through online synchronous positioning and real-time map creation. Using the machine vision target detection algorithm, an AI robot accurately identifies disinfection targets, independently plans the operation path and achieves accurate obstacle avoidance. According to preset environmental cleanliness requirements, the robot selects the targeted disinfection scheme, including calculating the required disinfectant dose, disinfection points, disinfection times, critical areas, and safety waiting times. In this way, the AI disinfection robot establishes an orderly and flexible environment-machine interaction.

Using a mobile robot platform as the carrier equipped with an ultraviolet lamp, ultra-dry mist hydrogen peroxide generator, plasma air purification, and other disinfection modules, the disinfection requirements of multiple environments within a hospital can be met simultaneously. The robot was developed using visual simultaneous localization and mapping algorithms [6,7,8,9]. To varying extents, these algorithms accomplish autonomous positioning and navigation in isolation wards (even indoors) and cover indoor paths without encountering dead ends. The fusion of indoor ultra-wideband centimeter-level positioning provides three-dimensional coordinates with positioning accuracy. As such, the robot quickly locates a patient’s bed and reaches the target location [10,11,12,13,14,15,16]. The environmental disinfection-intelligent robot customizes the disinfection mode to design various disinfection levels according to the needs of the scenario. After setting the disinfection mode, time, and location, the robot moves independently without human participation, truly realizing human-machine separation. During the pre-pandemic period in Wuhan, several intelligent disinfection robots served in hospitals, airports, subways, train stations, and public places with high crowd densities.

Using visual sensors and image recognition algorithms, the target disinfection scenario, key disinfection targets, and surrounding personnel can be identified. The corresponding disinfection mode operates as follows: (1) after automatic identification of the target, various disinfection plans and methods are adopted according to the environments and required cleanliness levels, including high-level disinfection for wards and ultraviolet disinfection for clinical laboratories; and (2) for key disinfection targets such as operating tables and cabinets, targeted disinfection measures can be adopted, including close-distance disinfection, local reinforcement disinfection, and surrounding ultraviolet radiation.

The robot builds maps and instantly locates the target through the fusion of multimodal sensors, thereby performing dynamic global and local planning. Based on powerful data processing capabilities, the robot improves navigation accuracy, obstacle recognition, and independent working ability and can freely respond to various complex medical environments in medical institutions.

The robot adopts ultra-dry mist atomization and uses a synergistic ultraviolet lamp as the main disinfection factor to realize multiple working modes: ultra-dry mist, single ultraviolet, and ultra-dry mist atomization synergistic ultraviolet. Depending on the specific disinfection requirements, several disinfection modes can be formulated to meet the requirements of medium- and high-level disinfection and achieve the management standards of hospital infection controls.

The robot is equipped with several disinfection modules and automatically matches disinfection solutions to the specific disinfection requirements across scenarios.

The robot uses high-definition wide-angle cameras and machine vision algorithms to identify disinfection scenes and targets accurately. These algorithms allow the intelligent selection of targeted disinfection solutions and enhanced disinfection (including key-point re-disinfection and surrounding disinfection). The algorithms also perform automatic safety sensing, generate site-clearing reminders, and report delayed work or emergency interruptions.

Disinfection information can be digitized, and standardized disinfection work procedures effectively ensure the quality of disinfection. The method, location, environment temperature and humidity, the time of disinfection work, and the accumulated use times of disinfection parts and accurate disinfectant dosage can be recorded and stored automatically. This feature facilitates checking the records to confirm whether disinfection work had been carried out according to regulations, whether any area had been overlooked, and whether the disinfection time met specifications.

To prevent and control the pandemic, the intelligent disinfection robot helps improve the closed loop of public health pandemic prevention and control. It achieves this goal through intelligent operation, informatized intelligent management, and disinfection standardized operating procedures for fever outpatient clinics and wards. The robotic model works with 5G networks to promote intelligent hospital construction.

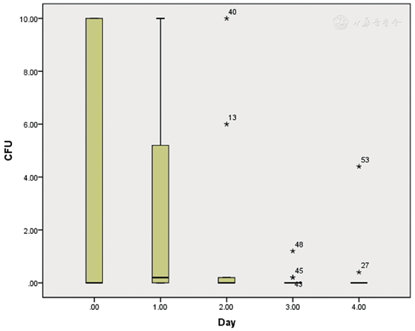

Throughout the COVID-19 pandemic, our team used intelligent disinfection robots to automate disinfection in admission areas. We also performed experiments to evaluate the effectiveness of robotic disinfection. From April 1 to 5, 2020, we randomly selected two isolation wards at Wuhan Union Hospital West Campus that possessed identical building layouts for the hospitalization of patients with severe COVID-19 and used intelligent robots to perform automated environmental disinfection of contaminated areas for three consecutive days. The air and surfaces in the environment of the ward areas were sampled continuously at fixed times (15:00-16:00) every day before (day 0), during (days 1-3), and after (day 4) the disinfection project to monitor the total number of microbial colonies. The robot operated along regular operation routes and times in each isolation ward to control for confounding factors. A total of 70 specimens (ten air and 60 surfaces) were collected for bacterio-logical cultures. Figure 3 shows the operational path of the intelligent disinfection robots in the isolation ward area and the distribution of the sampling sites.

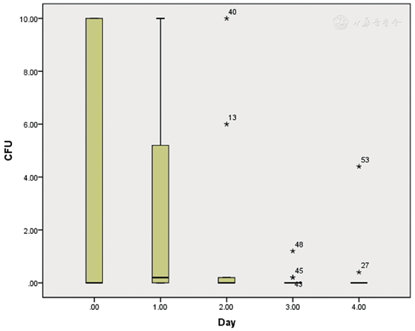

During the three days of the disinfection project, the total number of environmental microbial colonies in the ward areas was lower than before disinfection (Figure 4). A continuous downward trend remained at a low level for at least one day after the cessation of the intelligent robot disinfection. These findings suggest that the intelligent disinfection robot suppressed the total number of environmental microbial colonies in the isolation ward areas and helped prevent the indirect transmission of pathogens via environmental surfaces.

At present, several questions remain regarding the disinfection effect of intelligent disinfection robots in hospital environments. These questions concern whether the disinfection effect of intelligent disinfection robots differs from that of traditional manual disinfection by cleaners, the role played by intelligent disinfection robots in saving human and material resources, and how they can be paired with manual work to achieve optimal disinfection strategies and work schemes in future infectious disease outbreaks. These concerns require ongoing practice and study in real-world hospital settings.

Environmental cleaning and disinfection are the primary means of hospital infection prevention and control. Efficient environmental cleaning and disinfection play critical roles in reducing environmental contamination by pathogenic microorganisms and are necessary to interrupt exogenous hospital infection transmission pathways. The intelligent disinfection robot applies AI algorithms and robotic technology to the field of hospital disinfection. In essence, the model is a disinfection robot with a high level of independent self-sensing AI. The robot model uses intelligent scene recognition, independent sensing in the disinfection process, real-time disinfection process monitoring, intelligent planning, independent execution, and evaluation of the results. An intelligent disinfection robot can compensate for the shortcomings of existing disinfection methods, improve the quality of disinfection, and reduce the probability of infection. The disinfection process does not require human participation, reducing unnecessary direct contact between medical and nursing personnel and further protecting medical and nursing personnel from occupational injuries.

Adopting disinfection robots to disinfect the air and surfaces automatically can help reduce the human resources spent on environmental cleaning and disinfection, minimizing the risk of occupational exposure of disinfection staff. The robots facilitate informatized management of environmental disinfection and realize "cost control and efficiency improvement." The result is improvement in hospital infection management, reduction in occupational injuries, and overall improvement in medical care.

The robots used in this study were supported by the Shanghai Taimi Robot Technology Co., Ltd.; however, company personnel were not involved in the study design, data analysis, or interpretation.

Given his role as editorial board member, Yu Hu had no involvement in the peer-review of this article and has no access to information regarding its peer-review. Full responsibility for the editorial process for this article was delegated to Jing Sun and Zhuqingqing Cui.