This paper summarized the pressure control methods used in 16 large-scale production facilities in China for vaccines against foot-and-mouth disease virus and highly pathogenic avian influenza virus. We presented the pressure control modes, with their characteristics, of the "constant supply" mode - variable exhaust air volume system and the "constant supply" mode - constant exhaust air volume system. This paper analyzed the influence of common problems (e.g., pressure reference zero drift, positive pressure reversal and failure to restore the original normal working conditions after working condition conversion) on system stability during pressure control in BSL-3 large-scale production facilities and their solutions, providing references for the design and implementation of similar construction projects under the new situation.

2590-0536/© 2020 Chinese Medical Association Publishing House. Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/).

According to the Biological Safety Level-3 Standards for Veterinary Vaccine Manufacturers (Announcement No. 2573, hereinafter referred to as "the standard" ) issued in 2017 by the Ministry of Agriculture and Rural Affairs of the People's Republic of China, if the large-scale production facilities involve the operations of animal Class I and Class II pathogenic microorganisms (e.g., foot-and-mouth disease virus (FMDV), H5/H7 highly pathogenic avian influenza (HPAI) virus), their air cleaning system and facilities shall meet the requirements of biosafety Level-3 (BSL-3) protection.

The standard stipulates the following: 1) The containment area shall be maintained at absolute negative pressure at all times as in BSL-3 laboratory, and the pressure difference between main room (area) and its adjacent rooms shall not be less than 15 Pa; 2) For facilities working with zoonotic pathogens, air exhausted from restricted area may be partially recirculated into the same restricted area if air passes through a HEPA filter before it re-enters the containment area; 3) Exhaust air must be filtered by a two-stage HEPA filters before discharged; and 4) Air pressure control for the HVAC system requires that the containment area must maintain absolute negative pressure all the time, but there is no requirement for the pressure relationship of each room in the containment area in the conversion process [1].

Before the standard was released, China had no specific BSL-3 standard for large-scale production facilities other than two national standards for biosafety laboratories (i.e., GB 19489 and GB 50346). As a result, all enterprises implemented biosafety prevention and control policies based on their own understanding of the two national standards in the actual production process, with different scales and unavoidable flaws. Worldwide standards, such as The World Organization for Animal Health (OIE) standard for laboratories, The United States Department of Agriculture (USDA) Standard Appendix D-Agriculture Pathogen Biosafety, Agricultural Research Service (ARS) facilities design standards, the WHO Expert Committee on biological standardization and European Standard EN 1620-1996 (Biotechnology large-scale process and production-plant building according to the degree of hazard), either focused on laboratory operations or only provided a general description of large-scale production facility without detailed requirements. There are also some differences between European and North American systems. It is worth mentioning that both the European standard [2] and the American standard [3] classified FMDV and HPAI virus as BSL-3 or higher, but the specific standards are slightly different in detail. Therefore, it is of practical significance to develop a BSL-3 protection standard for animal vaccine production facilities in China.

The envelope of BSL-3 large-scale production facility in China is classified as the secondary barrier with certain air tightness requirements, which is similar to American standards [4]. Therefore, even a small amount of air volume change may lead to large fluctuations in room pressure during the operational process. If the air volume is not properly controlled, it will adversely effects on the pressure stability of main room (area). In this article, we will focus on the pressure control strategies for BSL-3 large-scale animal vaccine production facilities, combined with the current national standards and the author's testing and design experience, and put forward solutions to some common problems.

According to the standard, HVAC system of BSL-3 large-scale production facility must be able to control absolute negative pressure in the containment area at any time; meanwhile, ensure that the system can meet basic biosafety requirements when working conditions change (often with the highest biosafety risk), including system startup, operation, shutdown, standby air supply/exhaust fan switching and standby power supply switching.

Negative pressure is applied to the containment area to resist pressure fluctuation in BSL-3 facilities. However, for adjacent rooms, it is not necessary to keep overlarge pressure difference in the same containment area. Xu and colleagues [5] pointed out that the isolation effect of 5 Pa pressure difference is not significantly different from that of a 6-30 Pa pressure difference. Therefore, the pressure difference of other adjacent rooms is recommended to be 10 Pa in the containment area, except for the main room (area) and its adjacent rooms. However, no matter how high the pressure difference is, the isolation effect will disappear after the door is open. Therefore, it is unrealistic to prevent the exchange and spread of pollution by simply increasing the pressure difference [6] because the doors will be opened and closed frequently due to staff shuttle between rooms. However, if the negative pressure is maintained in the entire containment area, the safety of production will be assured. In addition, all staff wear personal protective equipment that are equivalent to the biosafety level of the product in the protective zone; therefore, thereare no biosafety concerns to staff. Furthermore, according to relevant GMP regulations, only one product can be produced in one unit at one time; thus, cross-contamination of the unit can be avoided.

Based on the characteristics of BSL-3 large-scale production facilities and their use described above, the standard only requires the containment area to maintain absolute negative pressure under any working conditions and does not care about the change of the relative pressure difference between rooms during the conversion process. The verifiability of pressure changes in the whole containment area shall be considered even the facilities in design phase. The logic sequences of the system air supply and exhaust fans shall be fully analyzed to ensure that the exhaust air volume is greater than the fresh air volume (return air condition) or the air supply volume (fresh air condition) at any time.

Air exhausted from a negative pressure HVAC system may be 100% discharged or partially recirculated into the same restricted area [7]. The latter can be divided into two types: system exhaust and partial room exhaust, both of which have same principles. The containment area is regarded as an approximately closed system: when the total exhaust air volume is greater than the total fresh air volume, the absolute negative pressure of the system can be achieved. Its derivation is as follows:

From (1) minus (2)

In Eqs. (1) to (3), QS is the air supply volume; QR is the return air volume; QF is the fresh air volume; QL is the increased exhaust air volume due to negative pressure infiltration; and QE is the exhaust air volume.

It can be seen from Eq. (3) that as long as the difference between the total exhaust air volume and the total fresh air volume (i.e., the air volume required to form negative pressure in an approximate ideal closed system) is greater than 0 (QL > 0); the absolute negative pressure can be achieved in the containment area. Furthermore, when QL is constant, dynamic balance can be achieved in the system [8].

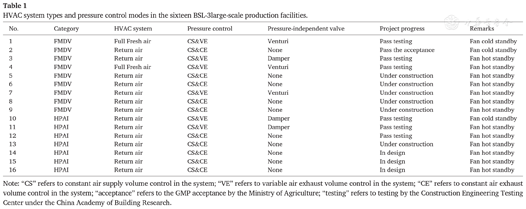

We analyzed sixteen BSL-3 large-scale production facilities in China which are designed for FMDV and HPAI virus production. These sixteen facilities were in different phases, from design, construction to engineering test being passed. Through the statistical analysis of the air conditioning forms and their pressure control methods used in the sixteen facilities, HVAC systems can be divided into two types. Type I has constant air supply and variable air exhaust, while type II has constant air supply and constant air exhaust. Table 1 shows the summary of HVAC system types and pressure control modes in the sixteen BSL-3 large-scale production facilities.

HVAC system types and pressure control modes in the sixteen BSL-3large-scale production facilities.

HVAC system types and pressure control modes in the sixteen BSL-3large-scale production facilities.

| No. | Category | HVAC system | Pressure control | Pressure-independent valve | Project progress | Remarks |

|---|---|---|---|---|---|---|

| 1 | FMDV | Full Fresh air | CS&VE | Venturi | Pass testing | Fan cold standby |

| 2 | FMDV | Return air | CS&CE | None | Pass the acceptance | Fan cold standby |

| 3 | FMDV | Return air | CS&VE | Damper | Pass testing | Fan hot standby |

| 4 | FMDV | Full Fresh air | CS&VE | Venturi | Pass testing | Fan hot standby |

| 5 | FMDV | Return air | CS&CE | None | Under construction | Fan hot standby |

| 6 | FMDV | Return air | CS&CE | None | Under construction | Fan hot standby |

| 7 | FMDV | Return air | CS&VE | Venturi | Under construction | Fan hot standby |

| 8 | FMDV | Return air | CS&CE | None | Under construction | Fan hot standby |

| 9 | FMDV | Return air | CS&CE | None | Under construction | Fan hot standby |

| 10 | HPAI | Return air | CS&VE | Damper | Pass testing | Fan cold standby |

| 11 | HPAI | Return air | CS&VE | Damper | Pass testing | Fan hot standby |

| 12 | HPAI | Return air | CS&CE | None | Pass testing | Fan hot standby |

| 13 | HPAI | Return air | CS&CE | None | Under construction | Fan hot standby |

| 14 | HPAI | Return air | CS&CE | None | In design | Fan hot standby |

| 15 | HPAI | Return air | CS&CE | None | In design | Fan hot standby |

| 16 | HPAI | Return air | CS&CE | None | In design | Fan hot standby |

Note: "CS" refers to constant air supply volume control in the system; "VE" refers to variable air exhaust volume control in the system; "CE" refers to constant air exhaust volume control in the system; "acceptance" refers to the GMP acceptance by the Ministry of Agriculture; "testing" refers to testing by the Construction Engineering Testing Center under the China Academy of Building Research.

As shown in Table 1, except for two facilities adopted 100% fresh air system, all the rest fourteen facilities adopted return HVAC system. In addition, 62.5% of the facilities are not equipped with pressure-independent devices, but they can still pass the testing, i.e., the containment areas are all under absolute negative pressure when working conditions are changed. This is because during the working condition conversion, the standard only puts forward for the whole containment area for keeping absolute negative pressure but does not require the negative pressure relationship for adjacent rooms (a biosafety laboratory has specific requirements for this). Then, the focus of pressure control is shifted from the room to the air supply and exhaust fan level, and the absolute negative pressure in the containment area can be fully guaranteed by controlling the start-stop sequence, frequency change and time difference in the air supply and exhaust fan units. Therefore, to provide reference for the design and implementation of similar construction projects, it is necessary to analyze different types of pressure control methods and their characteristics through a number of practical engineering cases.

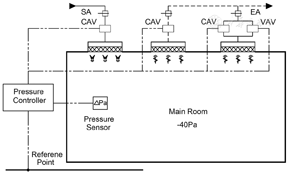

In the main room, the air supply volume is constant, and the air exhaust volume is variably. A constant air supply volume ensures that the air exchange rate of the workshop meets the requirements of design. The variable air volume valve (VAV) installed in the room exhaust duct is adjusted according to the room pressure to meet the pressure requirements in the room.

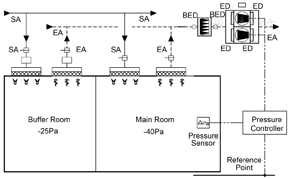

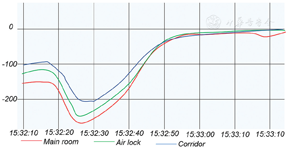

The room pressure is controlled by the "pressure tracking" method or the "residual air volume" method, and cascade control is formed with static pressure of the pipeline through resetting the room pressure difference to ensure absolute negative pressure when the system working conditions change. Taking a brand-new facility that passed the test for FMDV vaccine production as an example, as shown in Fig. 1, the negative pressure in the room forms a dynamic balance through the air volume difference between the indoor exhaust air and the supply air. Since the supply air is constant, the residual air volume can be reached by the adjustment of exhaust air volume in the room. At the same time, the negative pressure air volume difference in the room is reset according to differential pressure monitoring: whenever the system working conditions change, causing the changes in residual air volume required to maintain a fixed differential pressure, the differential pressure controller resets the exhaust air volume/supply air volume according to the deviation between the measured differential pressure value and the set value, finally making the pressure reach the set value.

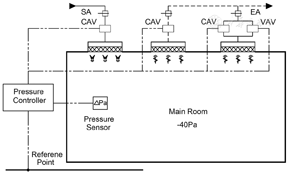

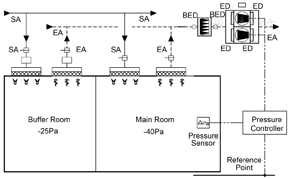

Instead of pressure-independent valves, HVAC system piping is only provided with manually regulating valves. According to engineering testing data, the pressure fluctuation of the vaccine production facility was a relatively slow process, and the filter resistance increased slowly; that is, the system operation changed little over a fairly long period of time. It is assumed that the pressure fluctuation change in the room is within the preset pressure difference range, and the pressure gradient in the room is obtained by manual debugging in the initial state of the system. During operation, the pressure gradient in the room is not automatically adjusted. The advantages of this method are economical investment and simple setup, and the actual measurement can also meet the requirements of the standard for the conversion of working conditions. When the working condition conversion occurs, the pressure guarantee is achieved by quickly switching the power supply and frequency of the total exhaust air and the total supply air blower (Fig. 2).

In a complex pressure control system, the absolute pressure sensor channels are usually collected into a stable tank, also called zero pressure tank. Connected with atmosphere, zero pressure tank is to ensure the stability of pressure values, offset the interference of external wind direction, wind force and other factors, and make the pressure reference points of all rooms the same.

Different from BSL-3 laboratories, BSL-3 large-scale production facilities have a large number of main rooms (areas) in the containment area. Since the absolute pressure reversal of each main room (area) during work condition conversion needs to be verified at the same time, multichannel pressure testing devices need to be used in the containment area to verify multiple main rooms at the same time. In the process of on-site verification, we found the absolute pressure changes of each room (the monitoring system built in the facility) displayed on the computer interface of the central control room often do not correspond to the current absolute pressure displayed by the indoor multichannel pressure testing device (third-party testing device).

After on-site investigation, we found that the facility used a zero-pressure tank to calibrate the zero-pressure point to the atmosphere, and the pressure sensors installed in each main room were collected into the zero-pressure tank through pipelines. Due to the large number of rooms and the complicated branch of pipelines, it is possible that the hose fell off and caused the zero-pressure point to shift, which will require manual on-site recovery. Therefore, to ensure the verification process during the on-site testing, calibrated instruments must be used to monitor the change in room pressure, instead of relying solely on the pressure sensor of the system.

In some facilities we have tested, positive pressure reversal still occurred in every main room during the shutdown of the system, even if the interlock logic relationship between the air supply and exhaust fans was normal and the exhaust shutdown time was prolonged.

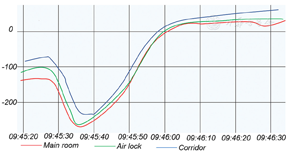

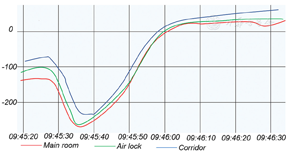

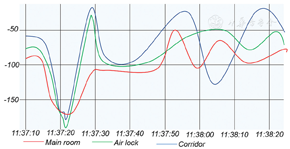

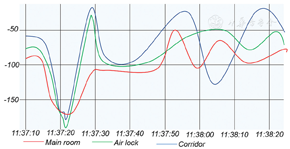

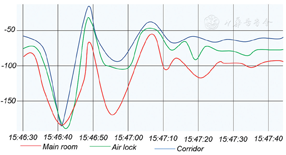

Fig. 3 showed the pressure curves during HVAC system shutdown in the containment area of a BSL-3 large-scale production facility for HPAI. After shutdown, the pressure of each room in the containment area first decreased to -200 Pa, then increased steadily, and finally stabilized at minor positive pressure and was not able to be recovered to 0 Pa. The interlock between supply and exhaust fans was confirmed normal. Our analysis discovered that, unlike BSL-3 laboratories, the layout of BSL-3 large-scale production facilities is more complex. BSL-3 laboratories are usually located in relatively independent areas within buildings, and the surrounding environment is the normal atmosphere. However, BSL-3 large-scale production facility is surrounded with support area which is at absolute positive pressure according to GMP rules. During normal operation, the surrounding positive pressure environment will leak into the negative pressure area through the wall panel gap, thus positive pressure reversal during shutdown was formed. The enclosure structure air tightness of this largescale production facility was checked. When the joint between the top plate and the wall plate with leak points was effectively sealed, the positive pressure reversal during HVAC system shutdown disappeared, as shown in Fig. 4.

For the convenience of maintenance, some facilities only maintain the main room (area) at a higher negative pressure (some of which can reach over -100 Pa) when working conditions are changed and do not restore the system to the original working condition again through switching. Such a long-term high negative pressure value poses a great challenge to the tightness of the enclosure structure. Fig. 5 showed high negative pressure was maintained in a BSL-3 large-scale production facility for FMDV. The negative pressure could not be switched to the original normal operation state after on-site simulation of the exhaust fan fails to promote the working conditions.

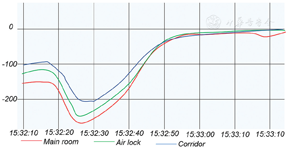

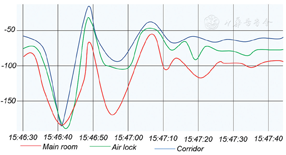

This kind of debugging scheme is common in the laboratory approach. It is believed that when the system fails and the working conditions are changed, what should be done is to ensure biological safety; the employees stop production operation and evacuate from the protection area. However, large-scale production facilities shall also meet the requirements of GMP. During batch production, the production system shall always keep normal operation. Stopping operation at the same time will lead to the scrapping of bacterial liquid in many production processes, causing serious losses to enterprises, which is also unacceptable for production enterprises. Based on this, the switching strategy must be adjusted to ensure that the backup fan can restore the pressure to a reasonable gradient after the exhaust fan fails and there is no absolute positive pressure reversal during the switching process. The actual site verification results after adjustment are shown in Fig. 6.

Fig. 6 shows the secondary test results after a period of debugging and rectification. It can be seen from the curve that, through the precise debugging of the frequency conversion rate of the air supply and exhaust fans after switching, the room pressure returned to close original value after the system is switched and pressure gradient can basically meet the standards and usage requirements.

From an engineering example, the currently adopted methods of "constant supply - variable exhaust air volume system "and "constant supply-constant exhaust air volume system" can meet all requirements of the standard for working condition conversion. The specific scheme can strike a balance between adjustability and economy according to the project investment.

Even if the air supply and exhaust fans are normally interlocked for the HVAC system, there are still some factors that, under changes in the working conditions, will cause the workshop to be unable to fully meet the requirements of laws, regulations and stable operation. Therefore, the practical use of BSL-3 workshops shall be comprehensively considered during the pressure control for it.

This research was supported and financially funded by the National Key R&D Program of China: Source identification, monitoring and integrated control of indoor microbial contamination (No. 2017YFC0702800).

The authors declare that there are no conflicts of interest.